The job of the our Technology Transfer Program is pretty straight-forward – bring NASA technology down to Earth. But, what does that actually mean? We’re glad you asked! We transfer the cool inventions NASA scientists develop for missions and license them to American businesses and entrepreneurs. And that is where the magic happens: those business-savvy licensees then create goods and products using our NASA tech. Once it hits the market, it becomes a “NASA Spinoff.”

If you’re imagining that sounds like a nightmare of paperwork and bureaucracy, think again. Our new automated “ATLAS” system helps you license your tech in no time — online and without any confusing forms or jargon.

So, sit back and browse this list of NASA tech ripe for the picking (well, licensing.) When you find something you like, follow the links below to apply for a license today! You can also browse the rest of our patent portfolio – full of hundreds of available technologies – by visiting technology.nasa.gov.

1. Soil Remediation with Plant-Fungal Combinations

Ahh, fungus. It’s fun to say and fun to eat—if you are a mushroom fan. But, did you know it can play a crucial role in helping trees grow in contaminated soil? Scientists at our Ames Research Center discovered that a special type of the fungus among us called “Ectomycorrhizal” (or EM for short) can help enhance the growth of trees in areas that have been damaged, such as those from oil spills.

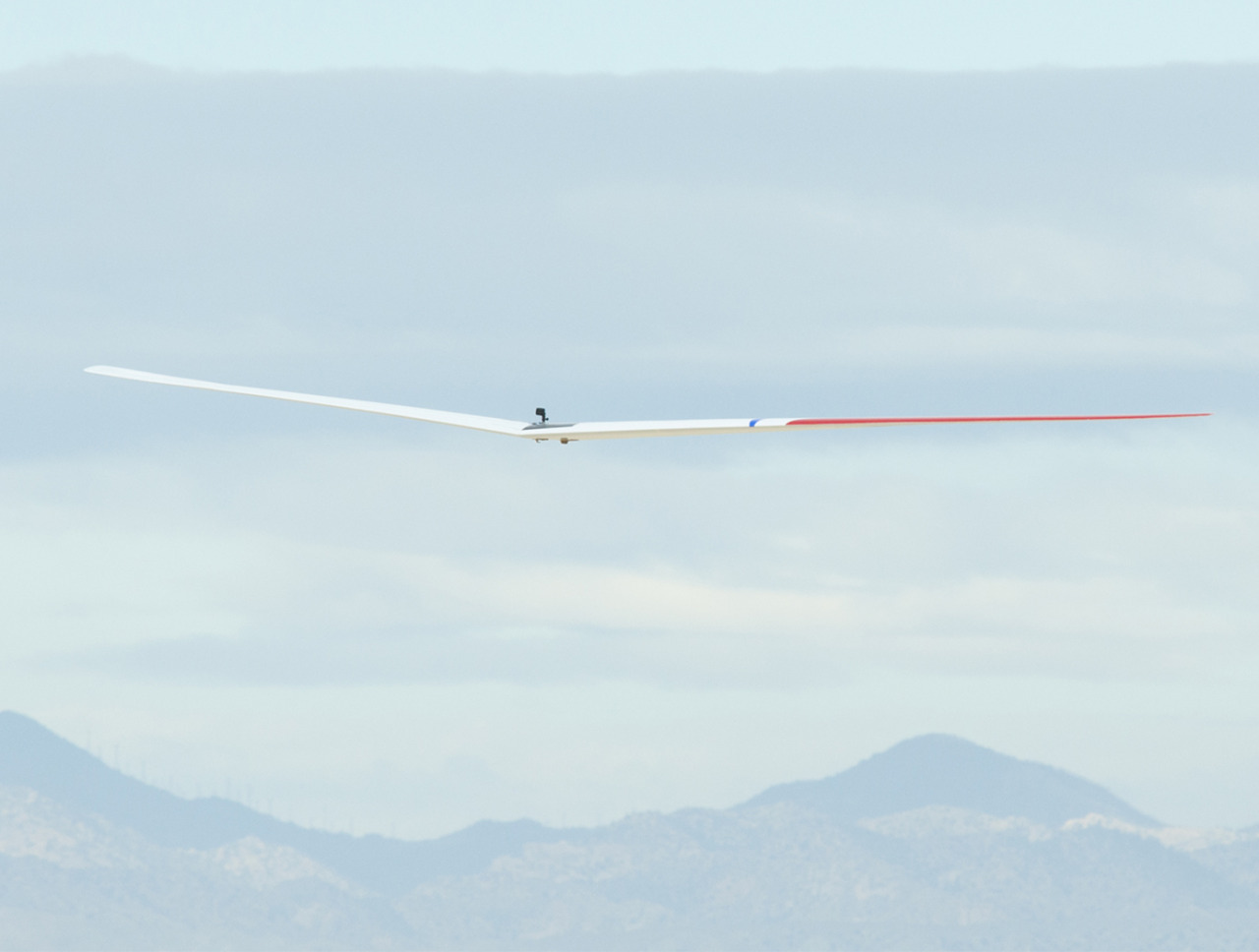

2. Preliminary Research Aerodynamic Design to Lower Drag

When it comes to aircraft, drag can be, well…a drag. Luckily, innovators at our Armstrong Flight Research Center are experimenting with a new wing design that removes adverse yaw (or unwanted twisting) and dramatically increases aircraft efficiency by reducing drag. Known as the “Preliminary Research Aerodynamic Design to Lower Drag (PRANDTL-D)” wing, this design addresses integrated bending moments and lift to achieve drag reduction.

3. Advancements in Nanomaterials

What do aircraft, batteries, and furniture have in common? They can ALL be improved with our nanomaterials. Nanomaterials are very tiny materials that often have unique optical, electrical and mechanical properties. Innovators at NASA’s Glenn Research Center have developed a suite of materials and methods to optimize the performance of nanomaterials by making them tougher and easier to process. This useful stuff can also help electronics, fuel cells and textiles.

4. Green Precision Cleaning

Industrial cleaning is hard work. It can also be expensive when you have to bring in chemicals to get things squeaky. Enter “Green Precision Cleaning,” which uses the nitrogen bubbles in water instead. The bubbles act as a scrubbing agent to clean equipment. Goddard Space Flight Center scientists developed this system for cleaning tubing and piping that significantly reduces cost and carbon consumption. Deionized water (or water that has been treated to remove most of its mineral ions) takes the place of costlier isopropyl alcohol (IPA) and also leaves no waste, which cuts out the pricey process of disposal. The cleaning system quickly and precisely removes all foreign matter from tubing and piping.

5. Self-Contained Device to Isolate Biological Samples

When it comes to working in space, smaller is always better. Innovators at our Johnson Space Center have developed a self-contained device for isolating microscopic materials like DNA, RNA, proteins, and cells without using pipettes or centrifuges. Think of this technology like a small briefcase full of what you need to isolate genetic material from organisms and microorganisms for analysis away from the lab. The device is also leak-proof, so users are protected from chemical hazards—which is good news for astronauts and Earth-bound scientists alike.

6. Portable, Rapid, Quiet Drill

When it comes to “bringing the boom,” NASA does it better than anyone. But sometimes, we know it’s better to keep the decibels low.

That’s why innovators at NASA’s Jet Propulsion Laboratory have developed a new handheld drilling device, suitable for a variety of operations, that is portable, rapid and quiet. Noise from drilling operations often becomes problematic because of the location or time of operations. Nighttime drilling can be particularly bothersome and the use of hearing protection in the high-noise areas may be difficult in some instances due to space restrictions or local hazards. This drill also weighs less than five pounds – talk about portable power.

7. Damage Detection System for Flat Surfaces

The ability to detect damage to surfaces can be crucial, especially on a sealed environment that sustains human life or critical equipment. Enter Kennedy Space Center’s damage detection system for flat composite surfaces.

The system is made up of layered composite material, with some of those layers containing the detection system imbedded right in.

Besides one day potentially keeping humans safe on Mars, this tech can also be used on aircrafts, military shelters, inflatable structures and more.

8. Sucrose-Treated Carbon Nanotube and Graphene Yarns and Sheets

We all know what a spoonful of sugar is capable of. But, who knew it could help make some materials stronger? Innovators at NASA’s Langley Research Center did! They use dehydrated sucrose to create yarns and woven sheets of carbon nanotubes and graphene.

The resulting materials are lightweight and strong. Sucrose is inexpensive and readily available, making the process cost-effective. Makes you look at the sweet substance a little differently, doesn’t it?

9. Ultrasonic Stir Welding

NASA scientists needed to find a way to friction weld that would be gentler on their welding equipment. Meet our next tech, ultrasonic stir welding.

NASA’s Marshall Space Flight Center engineers developed ultrasonic stir welding to join large pieces of very high-strength, high-melting-temperature metals such as titanium and Inconel. The addition of ultrasonic energy reduces damaging forces to the stir rod (or the piece of the unit that vibrates so fast, it joins the welding material together), extending its life. The technology also leaves behind a smoother, higher-quality weld.

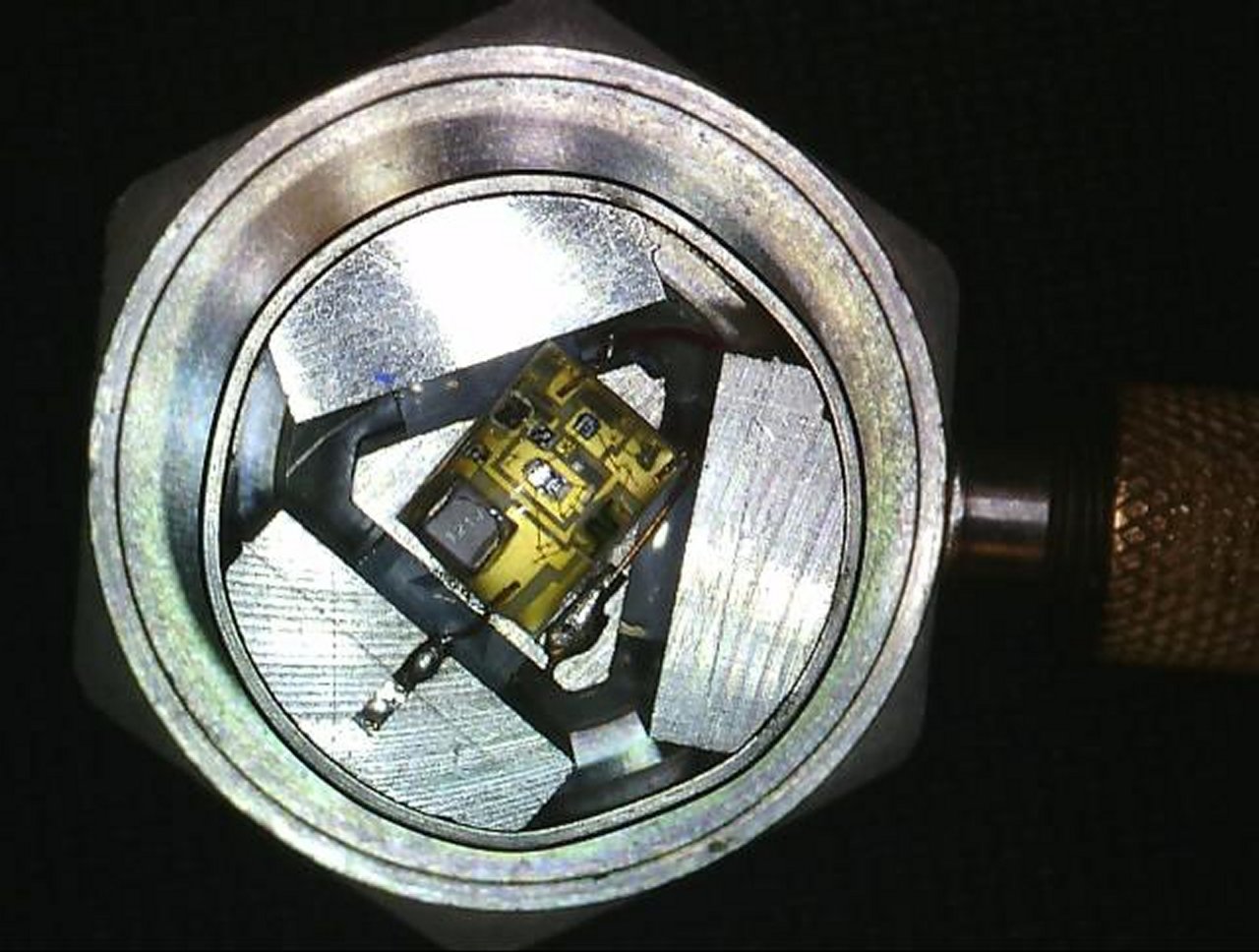

10. A Field Deployable PiezoElectric Gravimeter (PEG)

It’s important to know that the fuel pumping into rockets has remained fully liquid or if a harmful chemical is leaking out of its container. But each of those things, and the many other places sensors are routinely used, tends to require a specially designed, one-use device.

That can result in time-consuming and costly cycles of design, test and build, since there is no real standardized sensor that can be adapted and used more widely.

To meet this need, the PiezoElectric Gravimeter (PEG) was developed to provide a sensing system and method that can serve as the foundation for a wide variety of sensing applications.

See anything your business could use? Did anything inspire you to start your own company? If so, head to our website at technology.nasa.gov to check them out.

When you’ve found what you need, click, “Apply Now!” Our licensing system, ATLAS, will guide you through the rest.

If the items on this round-up didn’t grab you, that’s ok, too. We have hundreds of other technologies available and ready to license on our website.

And if you want to learn more about the technologies already being used all around you, visit spinoff.nasa.gov.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

source: nasa.tumblr.com